How a Global FMCG Leader Transformed Manufacturing Visibility

Problem Statement

A global FMCG player faced significant visibility gaps in its manufacturing operations. Critical KPIs such as System Line Efficiency (SLE), Asset Utilization (AU), and Plan vs. Output were only accessible at a monthly level, making it difficult to respond to issues quickly. Root cause analysis (RCA) was conducted on a quarterly or project-by-project basis, delaying corrective action and limiting continuous improvement.

With operations spanning 10–12 plants and multiple production lines per plant, the lack of unified, near real-time insights hindered performance optimization and timely decision-making.

Challenges

- Limited visibility into SLE, AU, and Plan vs. Output

- Manual RCA process, with delays due to project cycles limitations

- Siloed data across lines, plants, and functions, leading to fragmented insights

- Lag in identifying efficiency drops, leading to reactive firefighting instead of proactive management

Our Solution

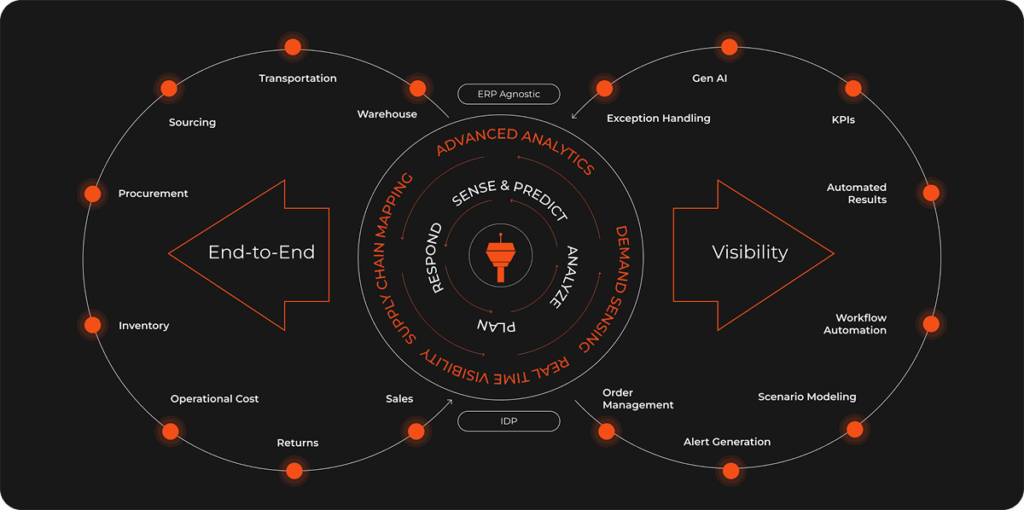

To bridge these gaps, Syren implemented a custom-built manufacturing Control Tower that provided day-level visibility into production KPIs across all targeted plants and lines. By tracking performance daily, diagnosing root causes instantly, and improving decision velocity, operational teams became more agile.

The Control Tower enabled multi-level visibility, from line operators to regional management, across more than a dozen plants and production lines. Once the disconnected datasets were merged into a single source of truth for a coherent operational overview, Syren added an intelligence layer with advanced analytics and GenAI enhanced stakeholder engagement.

Key Value Delivered

- Root Cause Analysis (RCA) to Diagnose Performance Drops: A causal ML-based RCA engine was integrated into the Control Tower, trained on historical observations to identify cause-and-effect relationships between KPIs and sub-KPIs. Causal Discovery generated the Graphical Causal Model with business constraints using algorithms such as DirectLiNGAM, PC, and NOTEARS. Causal inference, leveraging models like LinearRegression and HistGradientBoostingRegressor, is used to determine anomaly attribution from all sub-KPIs to target KPIs such as SLE, AU, and Plan vs Actual.

- Predictive Insights & Maintenance: The Causal Model with intervention and counterfactual helps predict sub-KPI behaviors and determine the optimal intervention needed to achieve the required target KPI.

- Recommendation Engine for Actionable Solutions: Rather than leaving users to interpret data manually, the system generates the insight as a narrative for easy understanding. It compares the best-in-class performance and seasonality and uses the optimization model to recommend optimal interventions to fix root causes.

- GenAI-Powered Intelligence Layer: Syren enhanced the Control Tower with GenAI capabilities by developing a multi-agent system. The SQLAgent model, developed using SQL context-based RAG, enables users to interact with the system through natural language and receive easily understandable data summaries. “What are the factors affecting the SLE in June 2025?” or “Name the top 3 contributors impacting the AU in July 2025”

The Control Tower now responds instantly with contextual, data-backed insights. This conversational interface made decision-making faster, more intuitive, and accessible for non-technical users.

GenAI also powered proactive alerts, summaries, and guided recommendations keeping teams one step ahead of disruptions.

Technical Layers

The Control Tower is built on a modular and scalable architecture, enabling seamless integration, advanced analytics, and AI-powered decision support.

Data Integration Layer

Unified structured and unstructured data from internal systems (ERP, WMS, CRM, etc.) and external sources (e.g., weather, macroeconomic indicators, third-party logistics feeds). Leveraged data virtualization and knowledge graph modeling to enable semantic search, context-aware querying, and near real-time ingestion at scale.

Analytics & Intelligence Layer

Served as the brain of the system, integrating with predictive, diagnostic, and prescriptive models powering the Control Tower. Included forecasting algorithms, anomaly detection, root cause analysis engines, optimization solvers, and GenAI components for summarization and recommendations. Embedded with conversational AI capabilities powered by RAG models and LLMs like Azure OpenAI and VannaAI. This layer handled end-to-end analytical processing, including ML pipeline orchestration and retraining.

Decision Orchestration Layer

Connected analytical outcomes to operational actions. This layer translated insights into system-level recommendations, triggered alerts, and enabled closed-loop execution (e.g., auto-generating POs in ERP). Integrated prioritization logic and scenario-based rule engines.

Collaboration & Communication Layer

Enabled collaboration across functions—planning, manufacturing, logistics, and sales—by sharing common insights and context. Served as the cross-functional glue between systems, users, and workflows to reduce silos and decision latency.

Presentation & Interaction Layer

The Control Tower’s user interface, optimized for ease-of-use and real-time interactivity. Users could ask natural language questions and get on-demand insights, thanks to the conversational AI capabilities powered by RAG models and LLMs, and view cross-functional KPIs, bottlenecks, and RCA summaries in a single interface.

Platform Services & Security Layer

Provided user and role-based access controls, audit logs, encryption protocols, and environment-level safeguards. Enabled scalable deployment, horizontal expansion, release management, and backup & recovery processes for uninterrupted operations.

Data Sources: System layer for both Internal (ERP, CRM, etc.) and external data sources (e.g., weather, tier N supplier information, news)

Conclusion

Modern manufacturing demands intelligence that drives action. Syren’s Control Tower helped this FMCG giant move from reactive firefighting to proactive performance management, powered by causal ML, GenAI, and real-time insights.

Whether you're aiming for faster root cause diagnosis, predictive interventions, or smarter cross-functional collaboration, Syren’s Control Tower framework can be tailored to your operations.