Something peculiar happened with air fryers in the U.S. during the pandemic.

People rushed to buy them. The demand for air fryers shot up abruptly. Retailers began maintaining surplus inventories to avoid empty shelves. Their suppliers also ordered extras from air fryer manufacturers, contributing to the excess stocks – and suddenly, there were too many air fryers as people stopped buying them.

Although the demand curve for air fryers stabilized later on, this incident serves as one of the best examples of the bullwhip effect in recent times.

Other items that were similarly subject to panic buying include toilet papers,

cleaning supplies, hand sanitizers, water, paper towels, etc.

Other items that were similarly subject to panic buying include toilet papers,

cleaning supplies, hand sanitizers, water, paper towels, etc.

What Is the Bullwhip Effect?

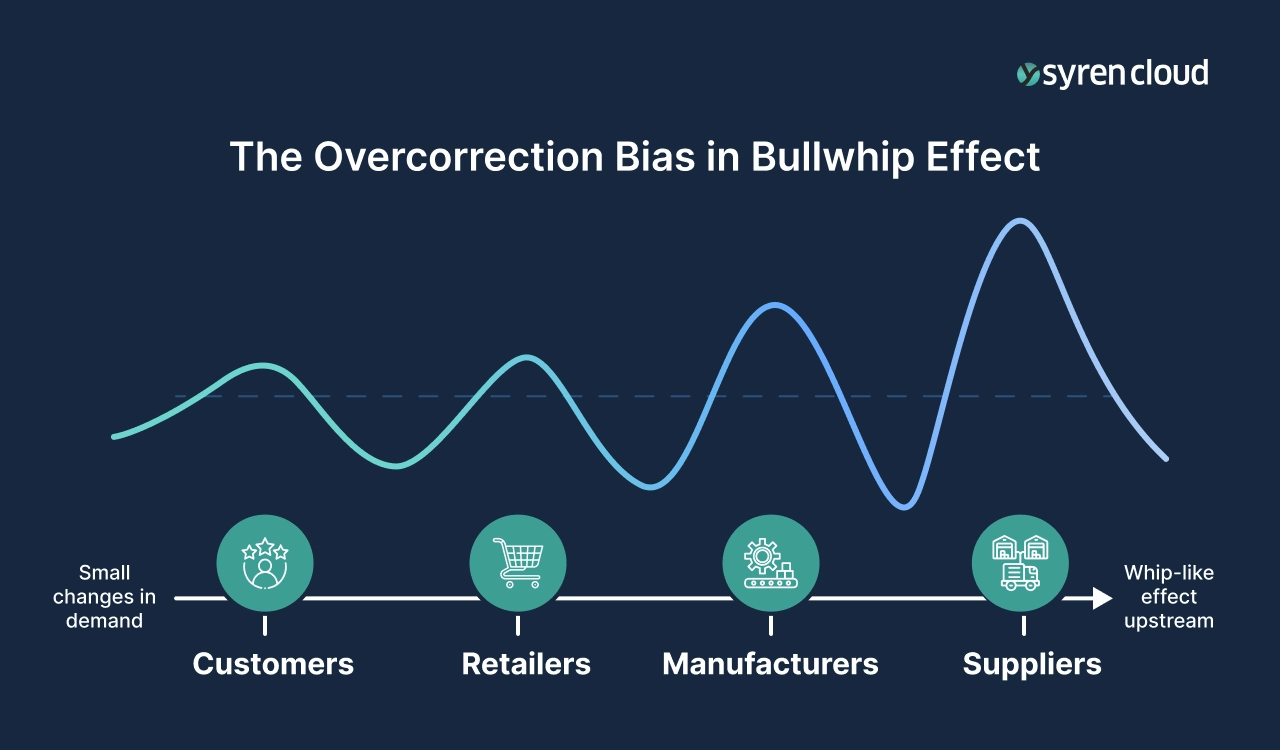

The bullwhip effect, first identified in the 1980s by the economists at Procter & Gamble, refers to a scenario where small fluctuations in retail demand become more pronounced as they move up to manufacturing in the supply chain.

Information on consumer demand for a particular product often gets increasingly skewed as it moves from the retailers to the manufacturers. These distortions result in:

- 1. Excess inventory throughout the network

- 2. Poor product forecasting leading to excess stocking or stockouts and

- 3. Higher inventory holding costs

- 4. Damaged brand image

- 5. Supply chain inefficiencies and disruptions

- 6. Severed supplier ties

This can be further explained by the overcorrection bias.

The Overcorrection Bias

Retailers often respond to temporary demand spikes by overcorrecting and placing orders for more items than they ordered before the shelves emptied. This happens because they understandably fear incidences of empty shelves that can drive regular customers to competitor stores with available inventory.

In a subsequent reaction, distributors place bigger orders with product manufacturers to cater to retailers’ newly inflated orders, adding to another 10-25% excess inventory. Just like retailers, they too fear losing their customers to rival distributors that have larger inventories.

Ultimately, manufacturers also overcorrect by churning out more products, just to be on the safer side. The overcorrection bias observed in the bullwhip effect results in creating excess inventory that is way higher than the existing market demand.

When Does the Bullwhip Effect Occur: 4 Common Causes

The bullwhip effect often occurs when:

Businesses have limited supply chain visibility

Be it giants like Nike or emerging companies like Everlane, supply chains are typically intricate and span across the world. This complexity is further amplified by factors such as diverse sales channels, demand fluctuations, increase in product variety (more SKUs), operations from multiple warehouses, etc. Lack of real-time visibility can hamper business performance, skew data and also reduce your network’s operational efficiency.

Data miscommunication

Miscommunication of data between stakeholders can create production misalignment causing manufacturing issues, demand shifts, transportation delays, or other bottlenecks in the supply chain. A secure, centralized data hub that handles real-time data and allows all stakeholders to access it is essential for avoiding phenomena like the bullwhip effect.

Demand misinterpretation

Skewed data on fluctuating consumer demand, inaccurate demand forecasting and misaligned production is a central theme to the bullwhip effect. It is recommended to adjust production levels calculated based on seasonality, emerging trends, historical data, existing demand, and much more. Manual forecasting is often inaccurate and time-consuming. However, advanced supply chain analytical solutions aid in demand forecasting, planning as well as provide invaluable recommendations for avoiding obsolete inventory.

Extended lead times

A delay in product lead time can prevent sellers from meeting consumer demand and may inadvertently result in the bullwhip effect. There are several factors that cause increased lead times, from changes in a manufacturer’s SLA to unexpected shortages in raw materials. Companies that proactively monitor these issues through real-time, end-to-end visibility solutions gain a competitive advantage. They are better equipped to navigate these disruptions smoothly and efficiently.

3 Ways to Soften the Impact of Bullwhip Effect

Improve visibility across your supply chain

Advanced supply chain visibility solutions integrate real-time data across all touchpoints, seamlessly collate data from across ERPs, WMS, POS, etc. to provide deep-tier visibility into your network. This allows your team some time to replenish inventory incase of unexpected demand spikes, supplier delays or more.

Supply Chain Expert Tip

Supply Chain Expert Tip

While many argue that ERP inventory systems are robust enough to handle their inventory management requirements, advanced visibility solutions integrate data from all sources – beyond ERPs.

Sign up for free demo and experience the power of real-time, multi-tier visibility.

Use a streamlined channel of data communication

Supply networks are noisy. With data coming in every second, it is almost impossible to manually keep track of potential delays or disruptions. A supply chain control tower seamlessly integrates data, cleans and models unstructured data, and provides it to you as the single source of truth. This makes decision-making simpler and more efficient.

Increase demand forecasting accuracy

Accurate demand forecasting is one of the most effective ways to reduce overstocking and prevent understocking. A supply chain control tower enables businesses to track inventory items to the last SKU and provides analytical reports showing slow moving objects, inventory holding costs, orders trend detection, historical sales data, and much more. You can also schedule automated alerts that send in replenishment requests to your suppliers, for instance.

Bullwhip effect is just one of the many disruptions that threaten the stability of your supply chain.

Supply chain disruptions like the bullwhip effect threaten the stability of your supply chain and weaken its operational performance. For starters, companies need to be proactively engaged in ensuring real-time data integration across all stages of the supply chain to mitigate risk.

Is Your Business Well-Prepared To Handle Supply Chain Challenges?

Only companies that build supply chains that are agile, adaptable, and aligned get ahead of their rivals. All three components are essential. Without any one of them, supply chains break down.

Great companies create supply chains that respond to abrupt changes in markets. Agility is critical because in most industries, both demand and supply fluctuate rapidly and widely. Supply chains typically cope by playing speed against costs, but agile ones respond both quickly and cost-efficiently.

Harvard researchers show that triple-A supply chain strategy enhances supply chain performance and that, in turn, positively impacts organizational efficiency.

What Does It Take to Build a Triple-A Supply Chain?

Successful Companies With Triple-A Supply Chains:

Agility

- Promote the synchronous flow of real-time information among supply chain partners

- Develop strong, long-term, collaborative relationships with suppliers

- Design production processes to facilitate desired schedules

- Build inventory buffers of inexpensive key components

- Create dependable logistics systems

- Provide recommendations for contingency plans

Adaptability

- Monitor world economies to identify new supply bases and markets

- Use intermediaries to develop fresh suppliers and logistics infrastructure

- Evaluate the needs of the ultimate customers as well as immediate customers

Alignment

- Freely exchanging information with suppliers and customers

- Clearly lay out pre-vetting criteria, roles and responsibilities for suppliers