AI in the pharmaceutical industry is already moving from pilots to full-scale implementation. It has become a strategic lever that enterprises can’t afford to ignore. With success stories in drug discovery and clinical trials to supply chain optimization and patient delivery, AI has proven its long-term value.

Pharma leaders are deploying artificial intelligence in pharma for better demand forecast, real-time cold-chain monitoring, and faster drug development, ensuring life-saving therapies reach patients faster and more reliably.

For example, Novartis uses AI-driven predictive analytics to align production with global demand. Meanwhile, GlaxoSmithKline applies AI to forecast allergy and flu seasons, so that the right medicines are stocked in the right regions.

Why 2025 Marks a Turning Point for AI in Pharma

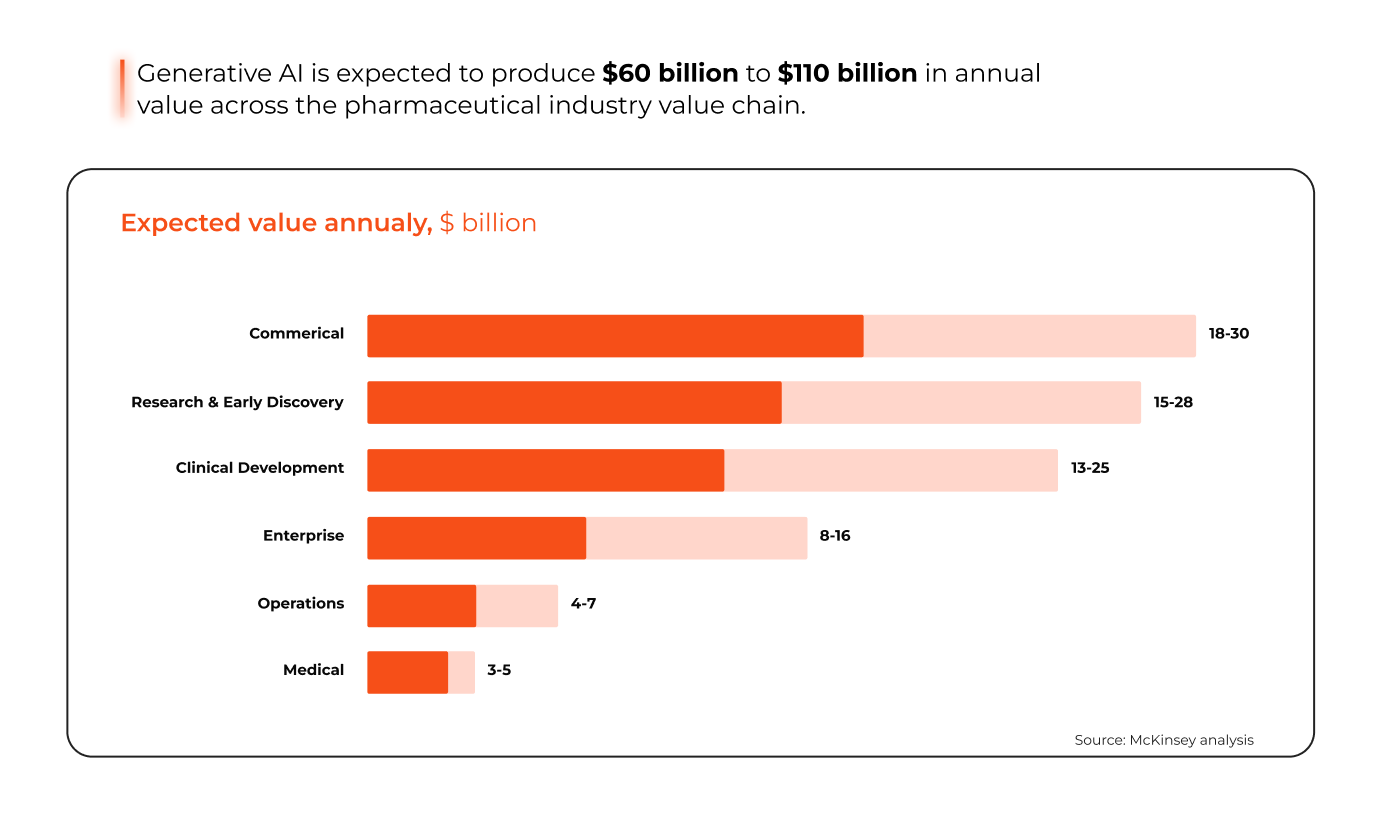

Generative AI maturity: Gen AI use cases in R&D, commercial planning, and knowledge synthesis have moved from proof-of-concept to production in multiple firms; McKinsey estimates generative AI could create $60–$110 billion in annual value for pharma and medtech.

Rapid market growth & investment: Industry reports project large CAGR for AI in healthcare markets, signaling widening budgets for commercial, clinical, and supply chain AI.

State of AI in Pharmaceutical Supply Chain

With AI, the pharma industry could go well beyond just creating more intelligent search tools when combined with machine learning and predictive analytics. It can solve some of the most significant problems in the pharmaceutical sector.

AI in Pharmaceutical Demand Forecasting

AI in pharma is already deployed to forecast demand by integrating seasonality, epidemiology data, and even external factors like weather, mobility, and web searches.

For example, Novo Nordisk is implementing AI-driven forecasting for inventory forecasts, cutting 50% forecast errors. Meanwhile, GlaxoSmithKline uses AI to forecast how the season for allergies and flu will take shape in different regions. They utilize this data to keep customers and retailers informed regarding distribution and stock.

Cold Chain Monitoring & Product Integrity

AI integration has made cold chain monitoring easier and more efficient. Each pharma enterprise dealing with vaccines or medicines that require temperature control needs more insights that go beyond just monitoring. Leveraging artificial intelligence in pharmaceutical industry, it is practically possible to anticipate risks and costs before they damage your bottom line.

For example, at Syren, we have implemented a sensor-driven AI-enabled cold chain monitoring process that integrates IoT feeds with shipment geolocation and predictive analytics. Now the enterprise can anticipate and predict temperature excursion before it occurs. The impact goes beyond cost saving; it safeguards trust in highly sensitive supply chains where a single breach in product integrity can lead to financial, legal, and reputational damage.

Enhancing ATP and OTIF Metrics

Pharmaceutical supply chains are highly complex, with perishable SKUs, regulatory release windows, and multi-echelon distribution.

Available-to-Promise (ATP) and On-Time In-Full (OTIF) are critical metrics in the pharmaceutical supply chain, reflecting a company's ability to meet customer demand accurately and promptly. AI contributes to these metrics by

Dynamic ATP Calculations

Syren’s Available-to-Promise (ATP) accelerator leverages predictive analytics to calculate delivery commitments in near real time. By analyzing the inventory levels, shipping timelines, and production schedules, Syren’s ATP ensures that the delivery promises are accurate. This implementation for a leading pharma supply chain improved the accuracy of their shipping and delivery date prediction by 90%

Improving OTIF Performance

AI-powered analytics provides end-to-end visibility across the supply chain. By integrating data from sales, production, and procurement, this enables companies to identify bottlenecks and root causes affecting On-Time In-Full (OTIF) performance, enabling targeted interventions. Clients implementing this have achieved measurable improvements, like a 10% boost in order fulfillment and an 85% reduction in manual efforts.

Quality Beyond Compliance

With use cases like predictive maintenance, real-time process monitoring, streamlined documentation, and compliance, AI is improving data accuracy, operational efficiency, regulatory compliance, and cost reduction.

- Real-Time Process Monitoring: AI facilitates real-time monitoring of the manufacturing process, detecting deviations from standard operating procedures (SOPs) in real-time.

- Predictive Maintenance: Based on equipment performance information, AI can predict probable failure before occurrence.

- Streamlined Documentation and Compliance: Compliance documentation can be integrated with AI-powered systems that minimize human intervention and error, saving up to 20,000 man-hours.

Drug Discovery & Development

AI in pharmaceutical industry is accelerating the discovery and development of new drugs, reducing R&D costs, and improving success rates. Here's how AI is making a significant impact:

AI-Driven Target Identification

AI algorithms have the potential to analyze large datasets, including genomic, proteomic, and clinical data, to identify potential drug targets efficiently. For example, Bristol Myers Squibb, Takeda Pharmaceuticals, and Astex Pharmaceuticals have collaborated to leverage proprietary data and train AI models to improve protein molecule interactions and speed up target identification.

Predictive Modeling for Molecule Design

AI can predict which molecular compounds can succeed, reducing continuous R&D and experiments.

For example, DSP-0038, a serotonin receptor modulator for Alzheimer related psychosis, progressed from discovery to Phase I trials in just one year, a process that typically takes 4–6 years.

Clinical Trial Optimization

AI can enhance clinical trial efficiency by optimizing patient recruitment, site identification, and real-time monitoring.

Research indicates that AI can enhance trial enrollment by 10–20% and predict enrollment performance, allowing for earlier interventions. For example, Isomorphic Labs (an Alphabet subsidiary) uses AI in therapeutic areas such as oncology and cardiovascular disease in order to accelerate drug development. Whereas drug discovery typically takes 5–10 years, the company believes it can shorten that timeframe by up to ten-fold.

Faster Drug Development

AI in pharmaceuticals can accelerate end-to-end development of new drugs. For example, Insilico Medicine’s Rentosertib, a selective TNIK inhibitor, moved from target discovery through Phases 0 and 1 trials in under 30 months.

The Future of Pharmaceuticals

The pharmaceutical industry is undergoing a revolution powered by Gen AI, promising developments to scale human health and well-being at an unprecedented scale, thanks to accelerating research and development processes.

The question is, are you a leader among the pioneers of this revolution?

Build an agile, resilient, and sustainable supply chain management for your businesses with Syren’s proven advanced strategies for optimized and seamless operations.