The regulatory outlook for 2025 is filled with uncertainty – it is dynamic at best. Governments and regulatory bodies are increasingly focused on sustainability, ethical sourcing, and transparency. This creates an increasingly complex and disruptive environment for supply chain enterprises.

Tasked with mounting restrictions and compliance requirements, the old tried and tested methods now seem obsolete. A new phase of regulatory scrutiny is prompting enterprises to rethink their supply chains from the ground up, ensuring they align with evolving mandates.

Globalization when it came into light within the world, seemed like such a new concept and one that could lead countries to economic liberalization. It allowed enterprises to prioritize cost and efficiency, with limited visibility beyond immediate suppliers. However, today’s regulatory environment demands full transparency and accountability. Authorities are now scrutinizing supply chain practices, requiring businesses to track and report on sourcing, labor conditions, and environmental impact. Regulatory frameworks such as the European Union’s Corporate Sustainability Reporting Directive (CSRD) and the U.S. Uyghur Forced Labor Prevention Act (UFLPA) set new standards for compliance.

The expectations are stringent. Enterprises must meet environmental, social, and ethical standards across the board and ensure that their suppliers do it as well.

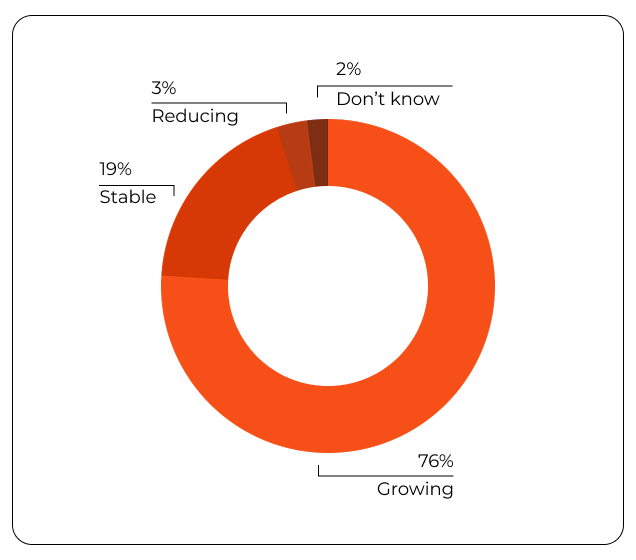

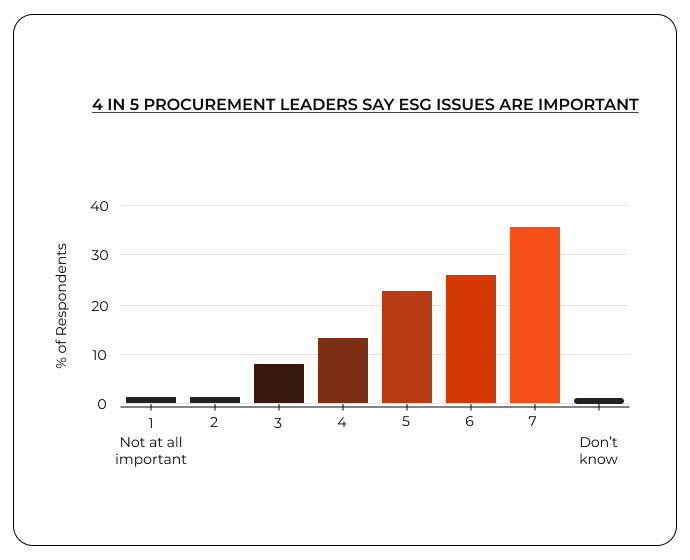

According to a study by CIPS Global State of Procurement & Supply Survey 2024, 95% believe ESG is a stable and growing priority among supply chain leaders.

*Source: 109 respondents were asked: “On a scale of 1 to 7 where 1 is not at all important and 7 is very important, how important are ESG issues within your organization?” and “Is the importance of ESG issues within your organization growing…?

We know regulatory compliance is vital but are enterprises ready with their regulatory strategies?

Global enterprises are now configuring compliance readiness that vary widely between regions and countries that may disrupt old practices. Here’s how they can navigate:

Use Transparency as a Distinguisher

Transparency is a primary concern and a fundamental necessity for enterprises working in the regulated environment in the economic climate.

When ethical practices are demonstrated over a long period of time, supply chain transparency and a commitment to ESG principles showcase clearly. It helps to be better positioned and builds credibility with regulators, investors, and consumers. Transparency as a practice bodes well with a strengthened brand reputation.

Developing clear reporting frameworks for supply chain practices is vital. It must align with transparency standards set by regulatory bodies. Immersing in technology that tracks and verifies supplier data can ensure enterprises to be confident in disclosing their material origins, environmental impact and labor practices across their supply chains.

Ensure Compliance Checks Happen Regularly, not Periodically

Have you ever pondered why compliance has often played a secondary role during audits and regulatory filings? It has been deemed statutorily not important, an afterthought. But with the current scrutiny, the approach is hazardous. The regulations today need high visibility and oversight throughout supply chains.

Enterprises must enforce compliance task forces for practicality purposes. They are good additions to have in supply chain teams. Their scope of work will include monitoring regulatory developments, tracking changes in supplier practices and ethics, and providing updates to the leadership. This ensures compliance is a focused approach across the board.

Enhance Supplier Audits and Scorecards

Enterprises must have supplier audits and scorecards in an organized format to manage complex and multi-tiered supply chains. It will require budget and support to increase the frequency and depth of supplier audits, mainly for high-risk suppliers. The scorecard must focus on facets like sustainability, labor practices, and ethical sourcing. Regularly sharing these results will help with accountability and encourage improvement from suppliers.

Enhance Contracts with Suppliers and Accountability

Enterprises today may not have the framework necessary to address modern regulatory needs with their suppliers. To ensure standardization, most enterprises focus on widely used terms and conditions and mostly overlook some of the key elements. Moreover, it is difficult to manage a horde of suppliers and to coordinate with them is time-consuming. To ensure compliance occurs, standard reporting practices historically win instead of customized compliance analysis.

While this practice was the norm earlier, today sharing real accountability is vital. Enterprises must revise supplier agreements to include specific clauses that address modern compliance concerns with relevant regulations such as sustainability, labor practices, and the overall environmental impact. Furthermore, regular audits and performance reviews must be conducted consistently to meet the compliance standards of the changing regulatory environment.

Conclusion

It is important to create an internal business framework to evaluate resilience over cost effective strategies that can only be gained from a diversified supplier network. By strengthening contingency plans for high-risk suppliers, enterprises can ensure business continuity. As regulatory scrutiny intensifies, supply chain leaders must pivot from reactive compliance to proactive compliance which involves strategic planning and management. By embracing transparency, redefining compliance as a continuous process, strengthening supplier accountability, enhancing audits and building resilient supply networks, enterprises can navigate the challenges posed by regulatory demands while managing to stay ahead of the curve.