Supply Chain Management vs. Logistics: Understanding the Differences in 2025

In 2025, the global logistics market is valued at $11.23 trillion ($9.98 trillion in 2024), projected to reach $23.14 trillion by 2034, growing at a CAGR of 8.36%.

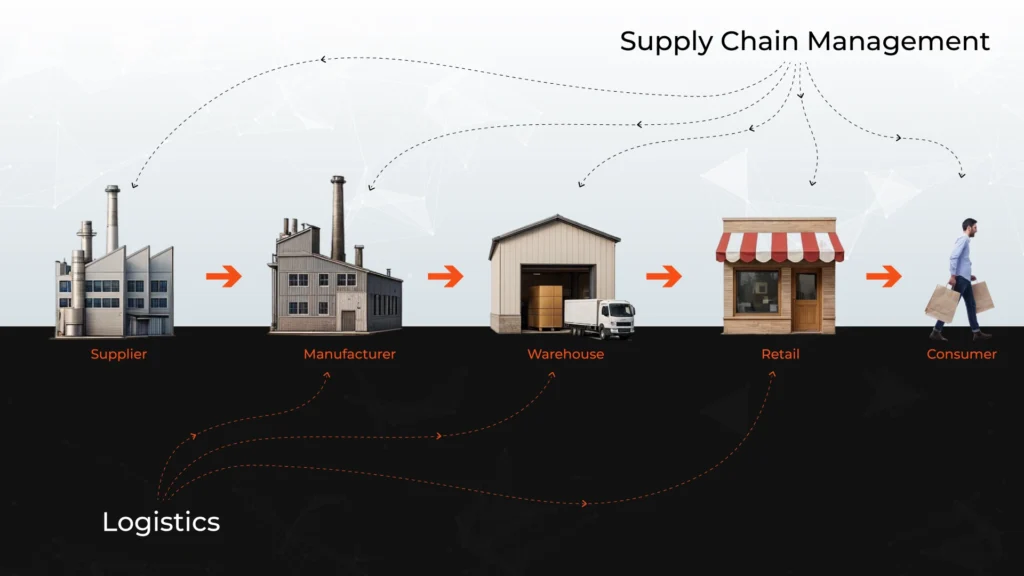

With this year-on-year projections and growth in the industry, it is important to understand the key difference between supply chain management (SCM) and logistics for businesses wanting to stay competitive, agile, and resilient. Even though both terms are closely related and used interchangeably, they represent different concepts in ensuring goods, information, and services.

To make it simple and easy to understand, we have narrowed down the key differences between supply chain management and logistics, because both are critical for competitiveness, resilience, and growth in 2025.

What is Supply Chain Management?

Supply Chain Management or SCM is the strategic coordination of sourcing, manufacturing, and distributing products from suppliers to customers. It involves each step from raw material purchasing to end-customer delivery.

Key elements of an SCM include

- Supplier relationship management

- Demand forecasting and planning

- Production scheduling

- Inventory optimization

- Distribution network design

- Risk mitigation and sustainability initiatives

According to Gartner (2025), 74% of companies are increasing their investments in supply chain resilience and visibility solutions post-pandemic disruptions.

What is Logistics?

Logistics is focused on the transportation, storage, and delivery of products from one point in the supply chain to another. This includes inventory management, warehousing, packaging, order fulfilment, and distribution.

Key Element of Logistics

- Transportation management

- Warehousing and distribution

- Inventory control

- Order fulfilment

- Reverse logistics (returns and recycling)

The warehouse automation market is projected to grow from $22.9 billion in 2024 to $41 billion by 2029 as companies embrace robotics and AI-driven logistics.

Key Differences Between SCM and Logistics: A Quick Glance

| Aspect | Supply Chain Management (SCM) | Logistics |

|---|---|---|

| Focus | End-to-end planning (sourcing, production, distribution) | Operational movement and storage of goods |

| Time Horizon | Long-term planning (quarterly, annual, multi-year) | Short-term operational cycles (daily, weekly) |

| Primary Goal | Maximize overall supply chain efficiency and resilience | Ensure timely, cost-effective product delivery |

| Tools and Systems | ERP, AI forecasting, supply chain control towers | TMS, WMS, GPS tracking, automation systems |

| Performance Metrics | Inventory turnover, supply chain cost, and demand accuracy | On-time delivery, transportation cost, and warehouse efficiency |

Understanding Supply Chain Management & Logistics with Real World Examples

1. Objective and Focus

SCM ensures that all components of the supply chain are in sync to maximize efficiency, minimize costs, and deliver customer satisfaction. For example, Walmart maintains low price points by using accurate forecasting, bulk purchasing, and strong supplier partnerships, streamlining its supply chain at scale.

The goal of logistics is to move goods from point A to B without any roadblocks, ensuring the right products reach the right place & time, with the least operational cost. For instance, FedEx optimizes delivery through real-time route optimization and truckload utilization, supported by strategically located warehouses.

2. Long-Term & Short-Term Planning

SCM is focused on optimizing the entire end-to-end process of getting a product from the supplier to the end consumer. For example, Coca-Cola has a diverse supplier network, enabling the company to reach every corner of the world. The brand has established trust, brand voice, and customer satisfaction with its agile supply chain network. With the correct SCM techniques, Coca-Cola has established strong supplier relationships, improved forecasting, and reduced overall supply chain costs.

Logistics focuses on the everyday operations of moving goods efficiently, optimizing transportation, warehousing, and inventory management. Let’s consider Amazon’s 24-hour, same-day, or two-day delivery programs. It has maximised its profits and customer satisfaction for its on-time-in-full deliveries.

3. Key Performance Metrics

SCM success is measured by metrics like total supply chain cost, order fulfilment rate, and inventory accuracy. Zara uses rapid product design, demand-driven production, and just-in-time inventory strategies to maintain agility and achieve high inventory turnover rates.

Logistics performance is evaluated through metrics like on-time delivery rates, transportation costs, and inventory turnover. FedEx consistently measures and improves on-time delivery rates and cost-per-package through its advanced logistics systems.

4. Technology and Tools

SCM leverages integrated technologies such as Enterprise Resource Planning (ERP), AI-powered demand forecasting tools, and advanced supply chain control towers for end-to-end visibility. Global companies are adopting AI-enabled supply chain control towers that aggregate data across multiple touchpoints, providing predictive insights to optimize inventory and production plans.

Logistics operations rely on systems like Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and real-time GPS tracking to optimize shipping and warehouse operations. UPS uses TMS platforms to continuously adjust and optimize delivery routes based on real-time data, reducing fuel costs and improving operational efficiency.

5. Business Impact

SCM supports the broader business model by enabling agile production schedules, minimizing waste, improving profitability, and building antifragile supply networks. Toyota perfected the Just-In-Time (JIT) manufacturing system, minimizing inventory holding and synchronizing supply deliveries precisely with production needs.

Logistics directly influences operational efficiency by optimizing transportation, warehousing, and delivery, leading to significant cost reductions. IKEA manages efficient global logistics networks, enabling cost savings that are passed on to customers through affordable pricing.

6. Timeframe of Execution

SCM typically involves long-term planning, from quarterly to multi-year strategies, anticipating market shifts and adjusting supply networks accordingly. Apple plans product launches and supply chain schedules well in advance, ensuring suppliers, manufacturers, and logistics partners are fully aligned for seamless product releases.

Logistics execution happens in short-term cycles, daily, weekly, or monthly, focusing on meeting immediate operational demands. FedEx manages daily logistics operations through dynamic scheduling to ensure efficient overnight deliveries and same-day services.

Conclusion

While SCM is the strategic framework that integrates all aspects of sourcing, production, and distribution, Logistics enables the right movement of goods from one point to another. Syren is helping enterprises reach this goal by providing AI & data-driven supply chain optimization solutions.

Is your company ready for future challenges?