Supply chains have been at a breaking point for a while now. Supply chain visibility and resilience played a crucial role in helping companies manage disruptions and balancing supply with demand. This paved the way for supply chain control towers that provided end-to-end visibility and transparency within global networks.

While supply chain visibility is a crucial first step, many companies stop there, unsure how to fully leverage its potential. Simply having end-to-end visibility isn’t enough to drive significant value.

The supply chain industry is at a breaking point. More than 70% of leaders need more than 2-3 system to make basic decisions, and 58% of billion-dollar companies struggle with critical blind spots.

New research from 200+ supply chain executives reveals:

- Only 22% of control towers drive meaningful action

- Where critical visibility gaps exist

- How leaders are addressing system fragmentation.

So, what makes a supply chain control tower truly worth the investment?

The true power of a control tower comes from its ability to help companies act based on the insights it provides. By integrating AI and machine learning, control towers can automatically raise alerts and recommend response actions. This allows businesses to move beyond reactive decision-making and towards orchestrated, automated solutions—streamlining operations, reducing manual tasks, and optimizing complex workflows for greater efficiency.

A supply chain control tower makes supply chain networks more customer-centric, sustainable, responsive, and agile. This is made possible by bringing together processes, technology infrastructure, data, and teams to drive enterprise value.

An end-to-end control tower must be built on four continuously evolving pillars:

- Use Case-Oriented Features

- Agile Supply Chain Frameworks

- Flexible Technological Infrastructure

- Robust Data Strategy and Governance

Use Case-Oriented Features

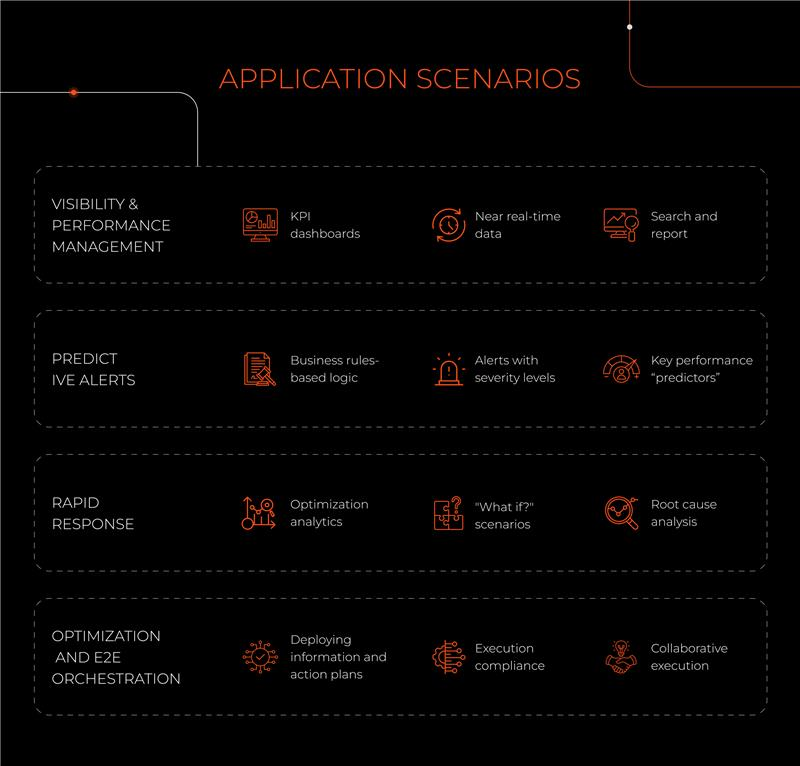

To derive the full value of a supply chain control tower, companies should identify specific use cases that will translate into business value. Such requirements will be facilitated by control tower capabilities like visibility, predictive alerts, scenario modeling, and automated operational execution which, combined, allow the control tower to predict and respond quickly while optimizing the execution of the supply network.

A Real-World Example of Warehouse Optimization through Supply Chain Control Towers

One example of how a supply chain control tower can drive significant business value comes from a leading technology company in the semiconductor industry. This company operates a highly specialized warehouse that serves as a critical hub for managing a vast range of components, from tiny screws to large steel frames. The warehouse is designed to support the assembly of customized machines in adjacent cleanrooms, where each machine has a unique set of requirements and materials.

The warehouse houses between 30,000 and 60,000 stock-keeping units (SKUs), with inventory fluctuating daily based on the machines being assembled. To optimize operations, the warehouse is divided into five distinct storage areas. These systems work together to quickly retrieve materials from across the warehouse whenever a cleanroom places an order.

These materials are then transported to a dedicated Material Intake & Contamination Control department, where they undergo a rigorous inspection, unpacking, and cleaning process in a UV-lit darkroom. The goal is to ensure that these materials are ready to be delivered to the cleanroom as a complete set—often within 30 minutes.

A control tower simplifies this scenario by providing real-time tracking of inventory across all storage areas, allowing for faster retrieval and reducing human errors. Additionally, it automates key tasks, such as the inspection and cleaning process, and coordinates seamlessly between different systems, ensuring that the right materials are delivered to the right place at the right time.

By integrating these technologies, the company can anticipate demand, optimize workflows, and deliver customized solutions with agility—demonstrating the real-world impact of control towers in enhancing supply chain efficiency and responsiveness.

Agile Supply Chain Frameworks

One key learning point for business across all industries is that supply chains need to be much more resilient. However, the solution does not lie in simply building redundant capacity or inventory. A cost-effective way out requires creating a more resilient supply chain with ‘intelligent visibility’.

Intelligent visibility provides the combined advantage of structural and dynamic visibility, supported by cutting-edge analytical techniques and artificial intelligence.

With structural visibility, companies can gain an overview of their operations either at a specific moment or over a defined period. This insight allows them to identify hidden challenges and gain a deeper understanding of factors such as:

- The locations of their suppliers

- The sites of their manufacturing operations

- The logistics routes they and their partners utilize

- The interconnectedness across the entire supply chain network

- Potential vulnerabilities and risks within the supply chain

On the other hand, dynamic visibility enables companies to track and react to events as they unfold. It represents a more advanced level of capability, offering insights into:

- The current location of products throughout the supply chain

- The performance of plants and warehouses

- The timing and location of disruptions

- The impact of disruptions and their specific effects

Advanced supply chain control towers like the Optima Control Tower provide a deeper view into multi-tier supply chain networks. AI-powered insights help businesses respond faster and make data-driven decisions to manage supply chain disruptions.

Both types of visibility are crucial, but when combined, they allow companies to identify their most vulnerable areas in the face of disruptions and prepare strategies to recover swiftly. Intelligent visibility further enhances this by enabling agile workflows, allowing companies to adapt more effectively and strengthen their resilience against various disruptions.

A control tower can transform the existing supply chain operations and will drive changes to existing organizational processes to run it. By driving greater collaboration, an SCCT also requires new customer-centric performance metrics and processes that can help create better benefits for the entire network.

Flexible Technological Infrastructure

A supply chain control tower is designed on flexible, cloud-based system architectures, which are essential for its ability to scale and integrate with additional entities and functional use cases as business requirements evolve and market technology advances.

By implementing the control tower through agile sprints focused on specific use cases, companies can expand to new entities, regions, or functional areas, while simultaneously enhancing its capabilities in areas like visibility, alerts, and response management.

Robust Data Strategy and Governance

A critical element of a supply chain control tower is its robust data strategy and governance framework. To ensure data is accurate, timely, and actionable, companies must establish clear data governance protocols. These include defining data ownership, establishing data quality standards, and setting up real-time data feeds across the supply chain network. This approach ensures that data from various sources—whether it be suppliers, warehouses, or logistics partners—remains consistent and reliable.

Governance also ensures data security and compliance with regulations, particularly when managing sensitive information such as customer orders or supplier contracts. With well-established governance practices, a supply chain control tower can offer transparency and trust, allowing companies to make informed decisions. In turn, this supports the seamless integration of data-driven insights into day-to-day operations, enabling faster, more accurate responses to supply chain disruptions.

Conclusion

Supply chain control towers are no longer just an advanced tool for monitoring and tracking; they have become the backbone of end-to-end supply chain optimization. By providing real-time visibility, predictive capabilities, and actionable insights, control towers empower businesses to respond proactively to disruptions and streamline operations. Whether it’s through structural visibility, dynamic insights, or AI-powered automation, these control towers enhance the agility, resilience, and efficiency of supply chains.

As companies increasingly embrace agile frameworks, flexible technology infrastructures, and robust data strategies, control towers evolve into key drivers of supply chain success. The integration of these systems and capabilities ultimately enables businesses to optimize their supply networks, reduce costs, and improve overall performance. In an era marked by uncertainty and rapid change, control towers ensure that companies can not only adapt to disruption but also thrive in a competitive, customer-centric landscape.