In today’s expectation-heavy supply chain environment, On-Time In-Full Delivery (OTIF-D) has become a defining performance benchmark for organizations across manufacturing, retail, distribution, and especially Healthcare & Life Sciences (HLS). Whether it’s critical medical devices, temperature-sensitive pharmaceuticals, or vision care products, customers expect and demand that organizations deliver exactly what was ordered, exactly when promised.

OTIF-D exists to answer a fundamental question:

“Did the customer get the right product, in the right quantity, at the right time?”

But in industries like healthcare and life sciences, OTIF serves a higher purpose than just being a service metric, it’s a matter of operational integrity, brand credibility, and above all, patient safety.

Why OTIF Matters Across Industries — and Why HLS Needs It Most

OTIF-D is widely used across consumer goods, industrial manufacturing, retail distribution, and automotive supply chains. But the stakes are significantly higher in Healthcare & Life Sciences, where delayed or incomplete deliveries can:

- Disrupt patient treatments

- Push surgeries or procedures off schedule

- Create compliance risks

- Trigger lost sales and penalties

- Impact drug availability and inventory planning

Achieving On-Time In-Full Delivery (OTIF-D) is mission-critical in the Health & Life Sciences (HLS) sector, where every order directly impacts patient care, compliance, and supply chain continuity. One missed milestone could potentially be a life-threatening risk.

Built on Databricks and powered by GenAI, Syren’s OTIF-D is featured on Databricks as an industry-specific GenAI solution. The platform combines Databricks Lakehouse, Gen-AI-powered intelligence framework, and Syren’s domain expertise to automate root-cause insights, improve delivery accuracy, and ensure reliable, compliant, and on-schedule fulfilment across global HLS operations.

What OTIF-D Really Means?

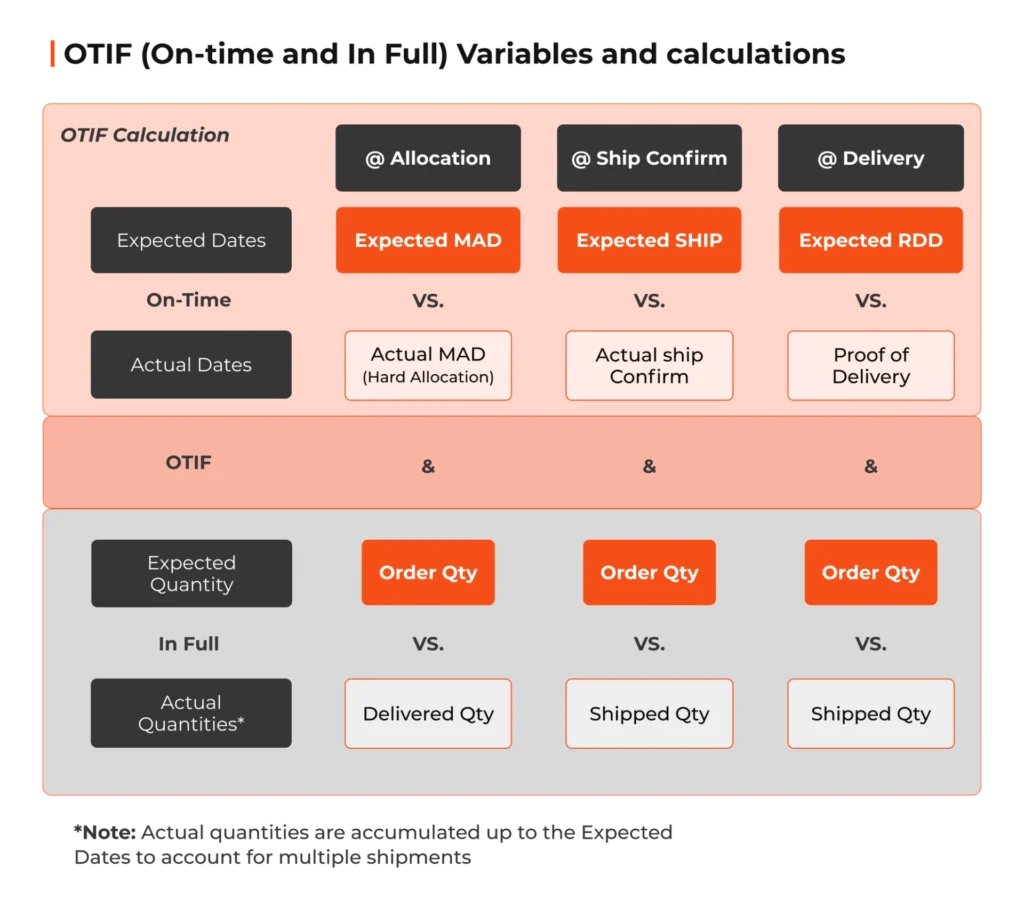

At its core, OTIF-D = On-Time & In-Full Delivery evaluates the following metrics:

- Was the delivery made on or before the committed date?

- Was the exact committed quantity delivered?

- Were all steps in the order lifecycle executed as expected?

Behind this simple definition lies a complex orchestration of planning data, transportation calendars, factory schedules, material availability, inventory checks, quality release cycles, and partner performance.

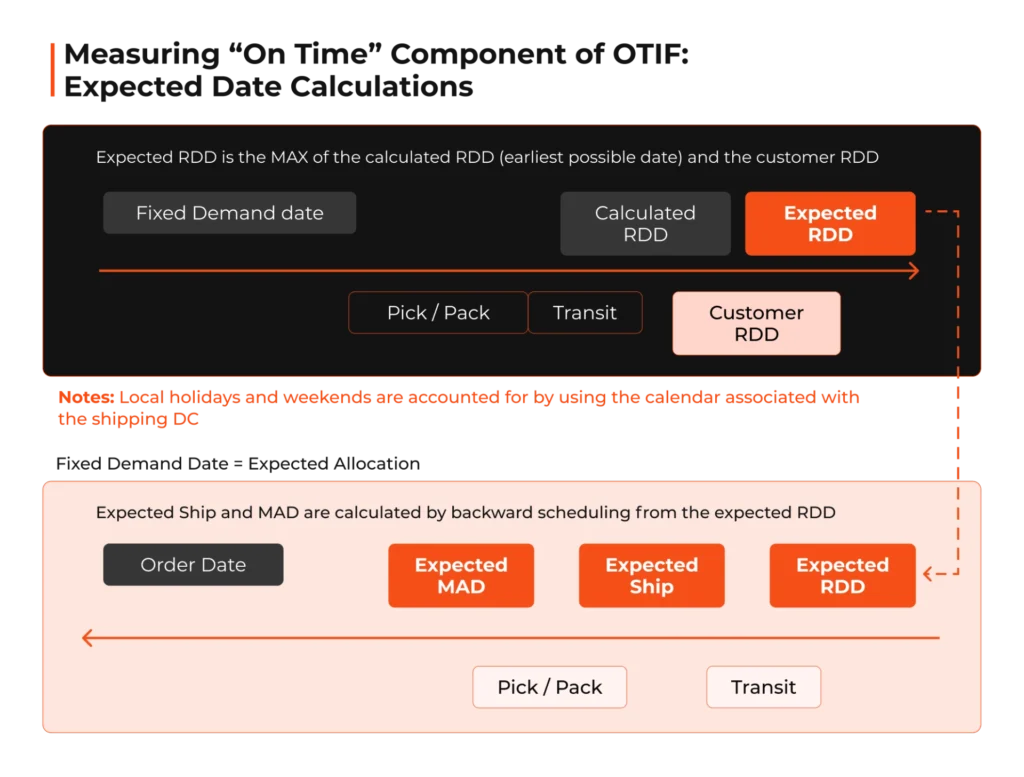

For every customer order, OTIF-D requires companies to calculate:

- Material Availability Date (MAD)

- Expected Shipping Date (ESD)

- Expected Delivery Date (EDD)

Adjusted for:

- Lead times

- Holiday calendars

- Regional working days

- Transit buffers

- Supply constraints

And only when all elements align does an order qualify as “On-Time” and “In-Full.”

The Challenge for OTIF in Healthcare & Life Sciences

The HLS supply chain is one of the most complex, regulated, and multi-stakeholder ecosystems in the world. Without a robust OTIF-D framework, organizations commonly face:

1. Fragmented Fulfillment Data

Order, warehouse, transportation, and customer data often sit siloed across ERP, WMS, TMS, and partner systems, making it nearly impossible to generate a unified OTIF view.

2. Limited Root-Cause Visibility

When OTIF fails, teams can’t pinpoint whether the issue was due to picking delays, production constraints, incorrect routing, or carrier performance.

3. Manual RCA and Error-Prone Follow-ups

Operations teams spend hours chasing PODs, calling carriers, validating transit updates, and reconciling exceptions through spreadsheets.

4. High Compliance and Documentation Burden

Missing or late Proof of Delivery (POD) leads to billing delays, audit risks, and customer service escalations.

5. Complex Regional Calendars

Different working days, holidays, cut-offs, and factory calendars make it hard to compute accurate delivery commitments.

These challenges ultimately lead to lost revenue, customer dissatisfaction, higher penalties, and a reactive supply chain.

How Syren’s OTIF-D Solution Transforms HLS Delivery Performance

Syren’s OTIF-D solution, powered by GenAI is built specifically to bring clarity, predictability, and proactive control into the HLS fulfillment ecosystem. Designed for pharmaceuticals, medical devices, and vision care, it helps organizations finally unify their supply chain data and take corrective action before delivery failures occur.

1. 30+ Fulfillment Milestones for End-to-End Traceability

Syren breaks down the full order lifecycle, starting from order creation and allocation to dispatch, transit, POD capture, and reconciliation. This visibility helps teams understand exactly where delays originate and what needs to be fixed.

2. Direct Logistics Partner Integration

Third-party logistics partners can upload PODs directly into the system, eliminating the need for manual follow-ups and speeding up billing and compliance processes.

3. Proactive Alerts & Automated Exception Handling

Automated notifications flag risks even before ahead of failures, helping teams take action before OTIF is impacted.

How A Global Pharma Enterprise Elevated OTIF with Syren’s OTIF-D

A leading global pharmaceutical company was struggling with fragmented visibility, manual POD chasing, inconsistent delivery reporting, and late upstream insights that directly hurt their OTIF performance.

Syren deployed OTIF-D to unify their order-to-delivery lifecycle, automate data flows, and give everyone from planning to logistics to customer service one reliable version of truth.

What the Pharma Company Achieved

85% Reduction in Manual Effort

Automated data ingestion, logistics partner integrations, and exception alerts eliminated the labor-heavy processes of tracking deliveries, collecting PODs, and reconciling mismatched data.

10% Improvement in Order Fulfillment

Real-time insights and proactive risk detection helped teams resolve delays earlier, leading to measurable uplift in OTIF performance.

Siloed systems and reactive firefighting were replaced with data consistency, real-time traceability, and collaborative logistics execution.

Technical Implementation

Delivering accurate OTIF reporting in HLS is extremely difficult because global enterprises operate across multiple sectors, each with different geographies, ERPs, logistics providers, and planning systems. Our client had four major HLS sectors within CDL. Each sector had its own rules, lead times, delivery journeys, holiday calendars, service providers, and reporting structures.

Syren’s architecture was designed specifically to absorb this diversity and output one global OTIF-D framework that works across HLS.

Syren’s Architecture - A Single OTIF Truth

1. Data Ingestion Across 20+ Systems and Sectors

Every source system emits data in different formats, frequencies, and field structures. Syren used Databricks to build a controlled ingestion layer that:

- Pulls files from ERPs, WMS, TMS, shipment trackers, and 3rd party feeds

- Normalizes naming conventions

- Applies sector-specific ingestion rules

- Handles daily, weekly, and event-driven flows

- Validates input quality before anything enters CDL

This ensured no bad data entered downstream OTIF calculations.

2. Transformation & OTIF Logic Engine in Databricks

This is where the real OTIF intelligence was built. Using Databricks, we processed and harmonized data across sectors using PySpark, SQL, and Pandas to:

- Standardize 30+ fulfillment milestones

- Compute sector-specific lead times

- Reconcile order lines to shipments

- Match dispatches to PODs from 3rd parties

- Stitch multi-leg deliveries

- Detect mismatches and missing events

- Calculate expected delivery dates vs. actual performance

This created a single, analytics-ready OTIF model for all markets, no matter the underlying source systems.

3. Pipeline Orchestration & Health Monitoring

Syren set up a multi-layer pipeline that ensures:

- Automatic daily refreshes

- Late-arriving data capture

- Dependency-driven workflows

- Alerts for data failures or missing feeds

- End-to-end lineage tracking

This was crucial for the pharma client where data reliability directly impacts patient-critical deliveries.

4. Unified OTIF-D Dashboards

Databricks AI/BI Dashboard sits on top of the final reporting layer(gold) and provides:

- Global OTIF reporting

- Sector-wise scorecards

- Root-cause analysis

- Region-wise and product-wise breakdown

- POD & logistics partner performance

- Upstream bottleneck insights (allocation, picking, staging, dispatch)

The templates allowed the client to go live in weeks, an activity that takes months.

What This Technical Stack Enabled

- One global OTIF definition, harmonized across sectors

- End-to-end delivery journey visibility for every SKU, country, and channel

- Automated POD ingestion from 3rd parties

- Proactive alerts for at-risk orders

- Regulatory-grade auditability for HLS

- Scalable onboarding of new regions and partners

The architecture wasn’t just cloud components—it was a purpose-built OTIF engine designed for the complexity of healthcare supply chains.

Conclusion

In a sector where every order impacts patient lives and clinical outcomes, HLS companies must invest in integrated and AI-enabled OTIF-D visibility to gain a stronger competitive edge, tighter compliance, and a more resilient, predictable supply chain.

Powered by our strategic partnership with Databricks, Syren’s OTIF-D brings together advanced analytics, enterprise-grade architecture, and deep supply chain expertise to help organizations gain a stronger competitive edge, tighter compliance, and a more resilient, predictable supply chain with every delivery.