Hyper-globalization and tough market competition present a formidable challenge for supply chains. Traditional approaches, often siloed and reactive, struggle to keep up with the increasing product volumes, suppliers, and constantly changing customer demands.

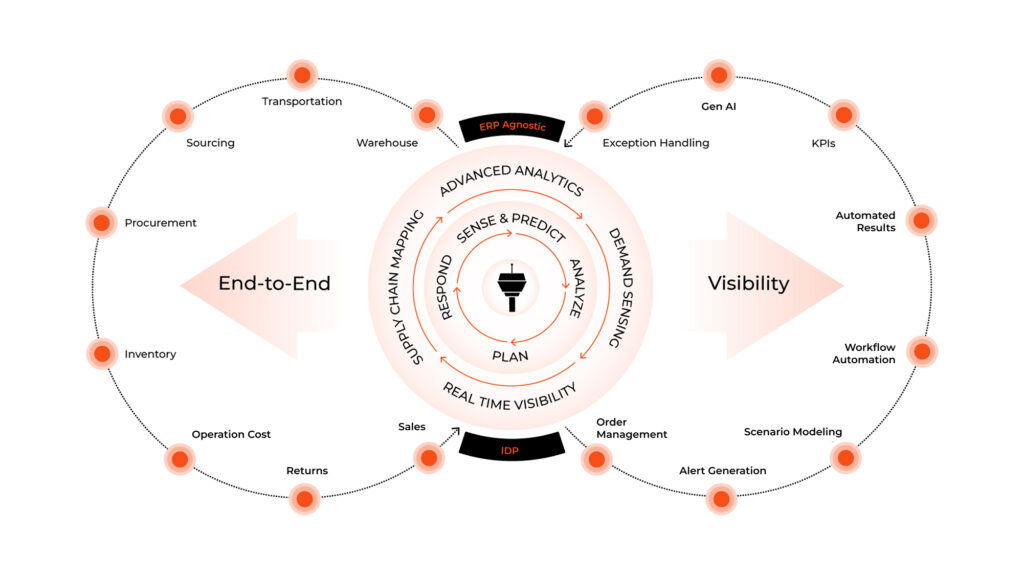

Supply chain control towers are a game-changing solution that offer a centralized platform for end-to-end visibility and control. By integrating data from across the entire supply chain ecosystem, control towers enable businesses to optimize operations, achieve greater visibility, and ultimately propel business success.

Supply Chain Control Towers for Streamlined Operations

A supply chain control tower pulls in data from ERP, WMS, TMS, suppliers, sensors, and even spreadsheets, capturing everything from shipments to delays. This includes raw materials suppliers, manufacturers, logistics providers responsible for transportation and warehousing, as well as retailers who deliver products to the end consumers. It then cleans and unifies this messy information into one view, offering real-time visibility into what’s moving, what’s stuck, and what’s performing smoothly across the supply chain.

Types of Supply Chain Control Towers

Supply chain control towers offer a diversified range of solutions, each catering to specific business needs. According to IBM, the most prominent control tower types are:

Logistics/Transportation Control Towers

Logistics/transportation control towers monitor shipments, carriers, and routes, helping businesses track goods in transit, minimize delays, and optimize transportation costs.

Fulfillment Control Towers

Acting as the central nervous system for order fulfillment, fulfillment control towers are centered on customer orders. They ensure accurate, timely deliveries while balancing efficiency and service levels.

Inventory Control Towers

Inventory control towers provide visibility into stock across warehouses, plants, and retail, helping reduce excess inventory, avoid stockouts, and improve availability. In essence, they transform reactive inventory management into a proactive strategy, enabling businesses to anticipate and address potential issues before they disrupt operations.

Supply Assurance Control Towers

Focused on suppliers and materials, supply assurance control towers identify risks such as shortages or quality issues and secure continuity of supply. These towers can be instrumental in supplier relationship management, fostering communication and collaboration to improve overall supply chain efficiency and identify cost-saving opportunities.

End-to-End (E2E) Supply Chain Control Towers

Offering the most comprehensive view, E2E supply chain control towers function like a central hub, providing complete visibility and control across the entire internal and external supply chain. This enables real-time decision-making and proactive risk management, ensuring a more resilient and agile supply chain.

Generative AI in Supply Chain Control Towers

AI is transforming control towers from reactive dashboards into proactive decision-making hubs. By analyzing vast volumes of supply chain data in real time, AI can predict disruptions, optimize inventory, recommend alternative routes, and even automate responses. This shift enables organizations to move beyond visibility, achieving true optimization across logistics, procurement, and fulfillment. With GenAI-powered insights, supply chain control towers deliver faster decisions, lower costs, and greater resilience in an increasingly unpredictable global environment. Here are some of the capabilities of GenAI in supply chain control towers.

- Pattern Recognition – Detection of unusual trends or anomalies in supply chain data early, allowing companies to prevent disruptions before they escalate.

- Optimal Routing – Use of real-time data to design the fastest and most cost-efficient transport routes and delivery schedules.

- Adaptive Sourcing – Recommendation of alternate suppliers instantly when primary sources face shortages, delays, or rising costs.

- Demand Forecasting – Prediction of customer demand changes more accurately by analyzing historical data and external market signals.

- Inventory Optimization – Maintaining the right stock levels across warehouses, lowering carrying costs, and avoiding both shortages and overstocks.

- Supplier Risk Assessment – Constant evaluation of supplier reliability and risks like quality issues, delays, or financial instability.

- Scenario Simulation – Running “what-if” simulations to test strategies and prepare for potential challenges before they occur.

Real-World Impact of GenAI in Supply Chain Control Towers

At Syren, we’ve moved beyond theory, deploying GenAI-powered control towers that directly address client challenges. By combining structured and unstructured data, our solutions have delivered faster insights, greater efficiency, and stronger compliance without compromising agility.

For a pharmaceutical client, we implemented a GenAI-powered control tower that unified data across suppliers, logistics partners, sites, and external manufacturers. The solution enhanced forecasting and planning, monitored batch and shelf-life risks, streamlined BOM management, and safeguarded cold-chain quality through temperature excursion tracking.

It also helped reduce slow-moving and obsolete inventory while improving OTIF by 55% and available-to-promise accuracy to more than 90%. By addressing these critical areas, the control tower enabled seamless collaboration, stronger compliance, and measurable gains in efficiency and reliability.

For another global FMCG client, limited visibility across lines and plants, manual root-cause analysis, and siloed data slowed decision-making and forced teams into reactive firefighting. We built a custom manufacturing control tower that delivered day-level visibility into production KPIs, enabling instant root-cause diagnosis and faster decisions.

By merging fragmented datasets into a single source of truth and layering advanced analytics with GenAI, the control tower provided multi-level visibility—from line operators to regional management—across more than a dozen plants. This transformation helped the client make decisions 2X faster and led to 40% quicker resolution across production lines.

When Do Companies Need a Supply Chain Control Tower and When Should AI Come In?

A supply chain control tower becomes essential when complexity outgrows traditional reporting. Companies struggling with fragmented data, limited visibility across suppliers, plants, or logistics, or constant firefighting due to delays and disruptions often find that a control tower provides the unified, real-time view they need. It’s the right step when supply chains span multiple geographies, involve external partners, or demand high service levels under strict compliance requirements.

AI should be layered into the control tower once basic visibility is in place and data pipelines are reasonably stable. At that point, AI adds predictive and prescriptive power—helping organizations not just see what’s happening, but anticipate disruptions, optimize decisions, and even automate responses. For enterprises aiming to move from reactive management to proactive, intelligence-driven operations, AI integration is the natural next step.

Need AI expertise and GenAI consultation for your Supply Chain? Learn More

Syren’s Agile and Efficient AI-Powered Supply Chain Control Towers

Syren’s Optima control tower goes beyond traditional offerings, incorporating AI and ML-powered capacity planning, dynamic reporting, and advanced scenario modeling. The Optima Control Tower is customizable for your industry and business needs and empowers businesses with:

- Strategic Decision Making: Gain comprehensive visibility into enterprise performance through insightful scorecards and dashboards.

- Standardized Processes: Ensure consistent and auditable execution through repeatable tasks.

- Enhanced Collaboration: Foster cross-functional communication and alignment among all stakeholders.

- Data-Driven Scenario Planning: Model different business strategies and measure their impact on achieving corporate goals.

A Future with AI-Enabled Supply Chain Control Towers

By offering real-time visibility, advanced analytics, and proactive risk management capabilities, control towers empower businesses to make data-driven decisions, optimize operations, and achieve greater supply chain resilience. As technology continues to evolve and the global supply chain landscape becomes increasingly complex, the adoption of control towers is poised to become the norm for businesses seeking to thrive in a competitive and dynamic marketplace.